How Tyre Degradation Affects Race Strategy: Strategies, Factors, and Techniques

Tyres are the only contact between a racecar and the track, which makes them the most important part of any racecar. No matter how much power the engine has, or the amount of downforce the aero package generates; if these loads cannot be effectively transferred through the tyres to generate grip, the car will not go faster.

Introduction to Tyre Degradation in Race Strategy

Unfortunately, a tyre’s ability to produce grip reduces over time. This degradation in tyre performance means the tyres don’t last as long, resulting in slower lap times and shorter stint lengths. Therefore, tyre degradation in motorsport can significantly affect race strategy, which is why teams and drivers put so much effort into trying to understand, predict and manage tyres.

Understanding Tyre Behaviour and Grip

How Rubber Behaves on Track

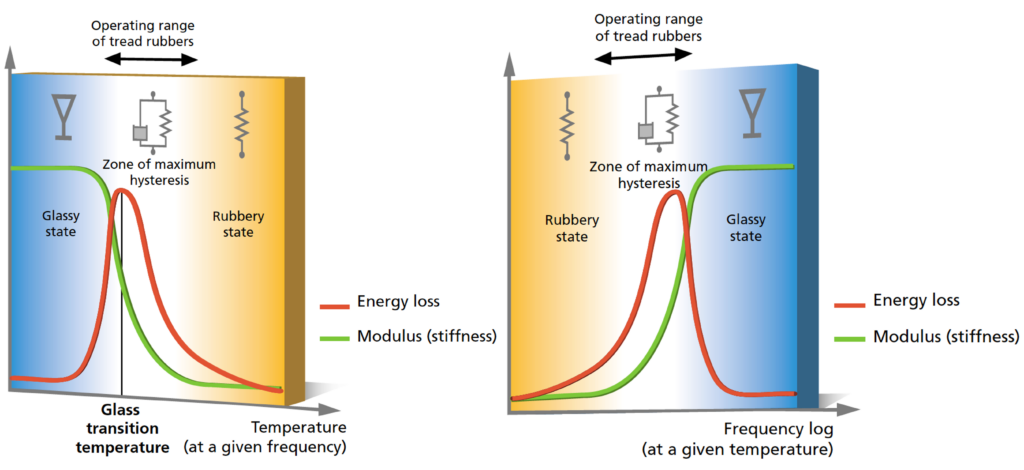

To understand tyres, we first need to grasp how rubber behaves. Rubber is viscoelastic, which means that once it has been deformed, it does not return to its original shape immediately. During this delay, energy is absorbed and converted into heat. The total amount of energy absorbed depends on the number of times the rubber is stressed and its temperature. For example, when rubber is cold, or excited by too high a frequency, it becomes hard and brittle. Whereas, when rubber is hot, or sliding slowly, it becomes elastic and rubbery.

The Role of Viscoelasticity in Grip Production

As the wheel rotates across the surface of the track, the viscoelastic nature of rubber allows the tyre to slip slightly, which generates the friction forces that produce grip. To maximise this grip, the rubber needs to be within a specific temperature range, so that it behaves elastically. This ensures that the maximum amount of rubber is in contact with the tarmac, increasing the tyre’s contact patch and therefore grip. If the rubber is outside of this temperature range, the tyre performance will degrade.

Key Causes of Tyre Degradation

There are three main causes of tyre degradation: wear, temperature and pressure.

1. Wear

As tyre rubber moves across the tarmac, it gradually wears away, leaving less rubber to generate heat. Consequently, tyre temperature decreases and the rubber becomes stiffer. This reduces grip, so the tyre slides more, which increases the wear and the cycle repeats.

2. Temperature

When the tyre is operating within its working temperature range, this level of wear, known as abrasion, is relatively consistent and leads to a gradual degradation in tyre performance, which is easy for the strategists to account for in their calculations. However, if rubber is overheated, it boils, rupturing the surface of the tyre, removing large chunks of rubber from the surface. On the other hand, if rubber is too cold, it becomes brittle and the surface starts to break away, leading to graining.

Both blistering and graining significantly reduce the area of the contact patch and therefore grip, which can lead to an extreme, non-linear loss of performance – a nightmare for strategists.

3. Pressure

The internal pressure of the tyre can also contribute to degradation. As tyre temperature increases, so does the running pressure. If too high, the tyre effectively balloons, reducing the size of the contact patch. This can encourage further overheating of the rubber at the contact patch, increasing the risk of blistering.

The Impact of Tyre Degradation on Race Strategy

The time lost per lap due to tyre degradation is one of the most important variables that strategists consider when defining strategy. Is it more effective to complete numerous pit stops but make that time back by racing on softer, and therefore, faster compounds? Or should pitstops be avoided in the hope that the driver can make the tyres last?

Optimizing Pit Stop Frequency Based on Tyre Wear

Then there is the question of when to pit. If degradation is high, the benefit of racing on fresh rubber makes the undercut a strong manoeuvre. But if degradation is low, the overcut may allow teams to capitalise on track position whilst opponents warm up their new set of tyres.

Tactics for Managing Tyre Degradation

Whether a team wants maximum performance for a qualifying lap, or to minimise degradation across a stint, the most effective way to manage tyre performance is to have both axles degrade at the same rate. Unfortunately, this is nearly impossible when each tyre is subjected to different loads during cornering. This is why teams employ every tactic they can to exploit and manage grip.

Warming Tyres for Optimal Performance

One of the most important tactics is warming the tyres effectively. Before a session, tyre blankets and ovens are used to preheat tyres, while in championships where this is not allowed, teams will often leave tyres out in the sun. Preheating the tyres not only moves them towards the optimum temperature range but also reduces the increase in running pressure. If the tyres were warmed up from cold, the internal pressure would increase dramatically, leading to the tyre ballooning and a much smaller contact patch.

Once on track, the driver then needs to warm the tyres up consistently and slowly, avoiding any lock-ups or sliding that could damage the surface of the rubber. Consequently, drivers will often complete an outlap and a preplap to get both axles up to temperature before starting the qualifying lap. During safety car and yellow flag periods, drivers will weave on the straights to keep up tyre temperatures and avoid locking up into the first corner once the safety car is in.

Tyre warm up can also affect the strategic decisions during a race. Sometimes teams will opt for the undercut, even if it sacrifices track position, to allow their driver to get the tyres up to temperature a lap earlier than their rival. This way, when their competitor leaves the pits ahead of them on colder tyres, they have the grip available to overtake. This is mostly seen during races with damp or changing conditions or with harder tyres where the warm up phase can be several laps.

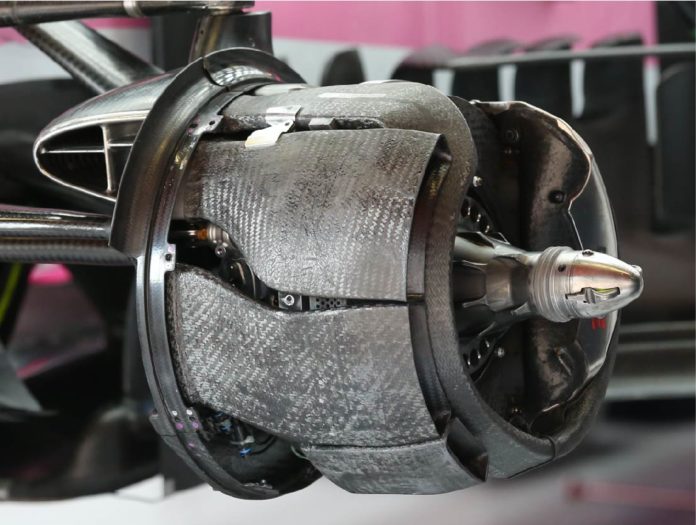

The driver can also have a significant influence on tyre management during stints. For example, they can adjust the brake bias to put more energy into the front or rear brakes, which in turn warms the tyres through rim heating. This is where the fresh, cool air used to cool the brakes is then heated to hundreds of degrees. This heat then transfers to the wheel rim, which radiates through to the tyres. In Formula 1, heating the wheel rim by 10degC can equate to approximately 1degC increase in tyre carcass temperature – which could be the difference between being in or out of the optimum temperature range.

In-Race Techniques: Brake Bias and Lift-and-Coast

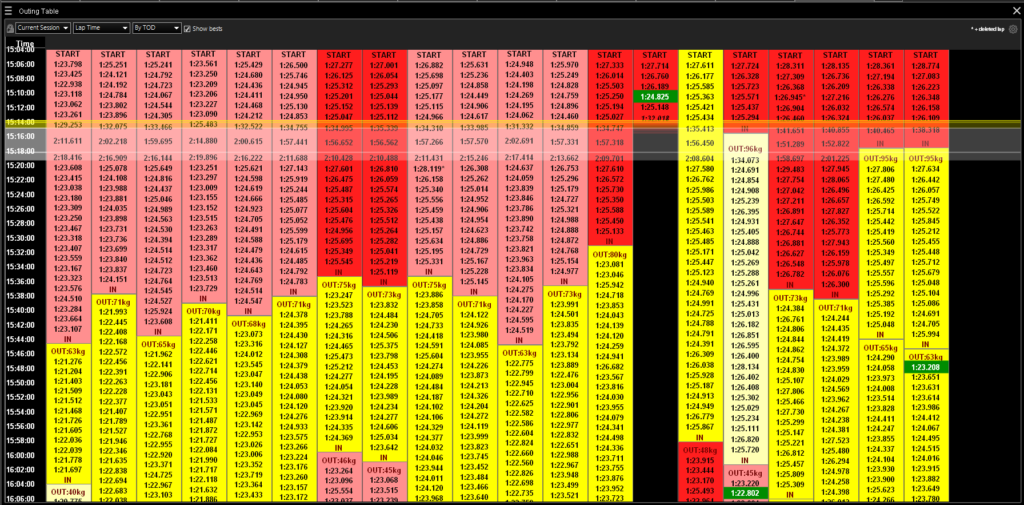

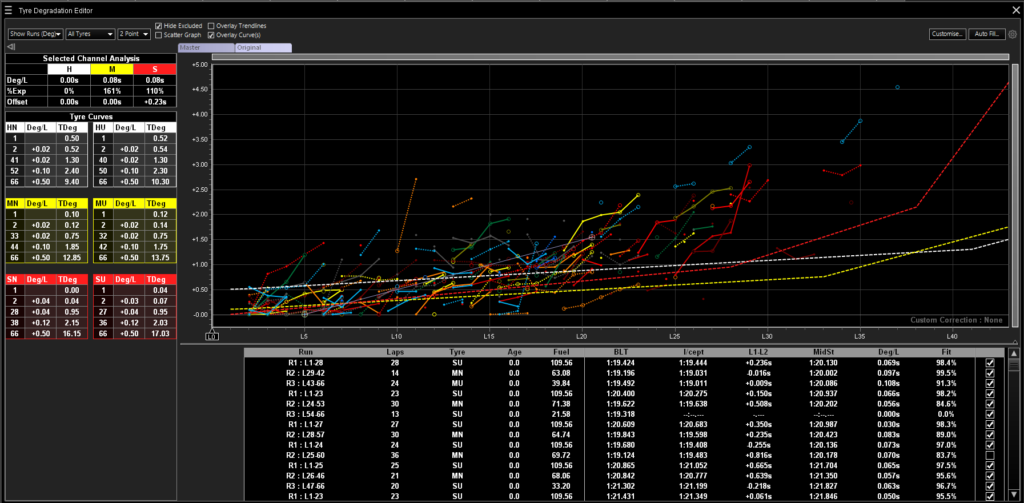

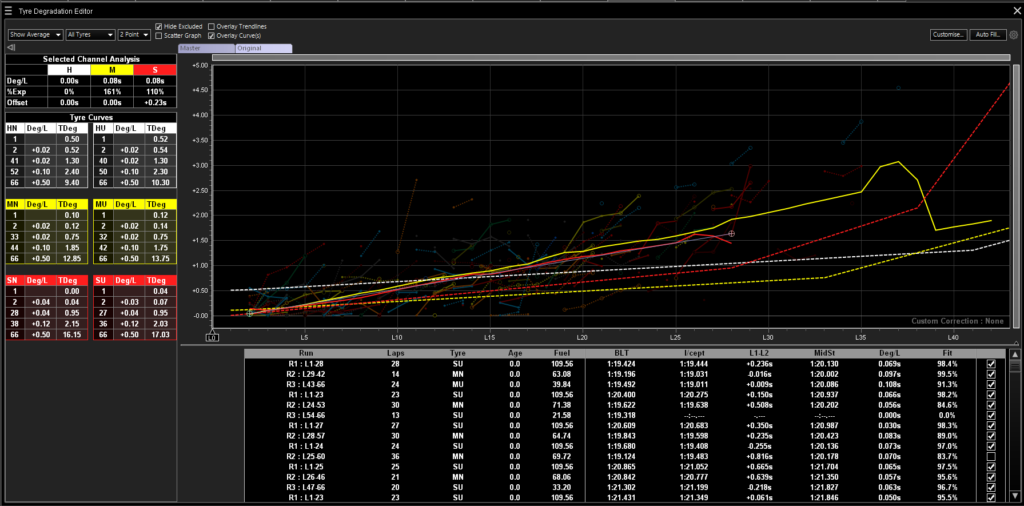

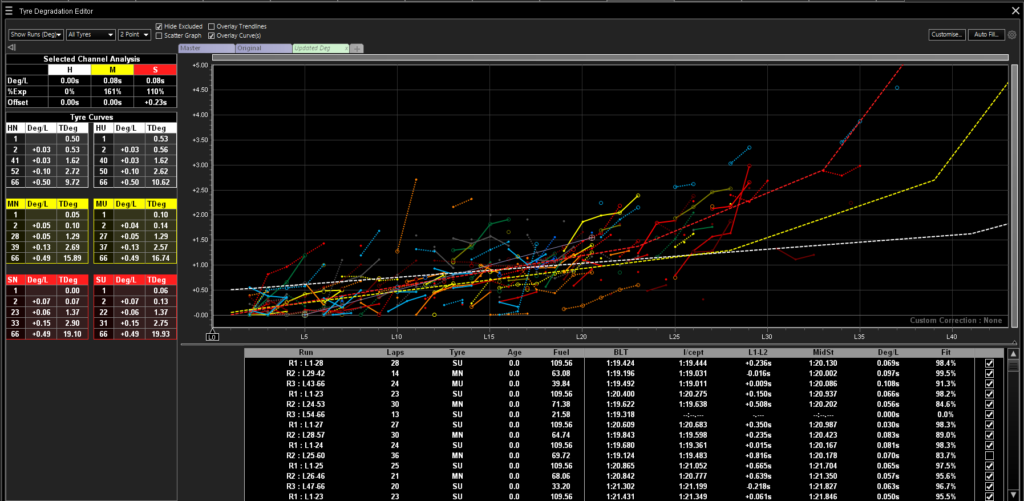

In scenarios where tyres are overheating, drivers can lift and coast to reduce the load on each tyre. If done effectively on certain corners of the lap, drivers can often protect the tyres, without actually losing any lap time. The amount of tyre management required is defined before the race, by using tyre degradation curves and race planner views in race strategy software such as RaceWatch.

RaceWatch: An Essential Tool for Tyre Degradation Analysis

Strategists can then determine several race plans, each with a different pit stop strategy and work with the driver to identify the amount of lift and coast needed to make the tyres last. Therefore, during the race if tyre degradation is different to expected, drivers will be told to ‘switch to plan B’. This not only tells them they have switched to a different pit stop strategy, but they also now need to drive to the pre-defined deltas to make the tyres last.

Planning and Adjusting Strategy with RaceWatch

Managing tyre degradation is the secret to executing a winning race strategy and software like RaceWatch can provide the crucial information engineers need to make quick, yet accurate decisions. There have been countless occasions across championships, where looking after the tyres has helped teams avoid that all important pit stop to claim the top step of the podium.

Article written by: Gemma Hatton

*This content was originally published April, 2024 but has since been updated to maintain the accuracy of insight and user experience.